Everything You Need to Know About Fiberglass Pools

Fiberglass Pool Information | Installation & Construction | Cost and Pricing | Swimming Pool FAQs

So you're thinking about getting a pool.

You've narrowed your choices down to an inground fiberglass pool... or something else. While we offer a wealth of information on various types of inground and above-ground pools, we specialize in fiberglass pools and have extensive knowledge and expertise in their design and installation.

We specialize in fiberglass pools, and the overwhelming positive feedback from our customers continues to validate that decision every day. One key reason for our success has been our emphasis on education -- we want everyone to make the best choice for their circumstances, even if it means some folks choose other types of pools for their backyards.

So, is a fiberglass pool right for you? Let's find out!

What is a fiberglass pool?

The main structure of a fiberglass pool is a single one-piece structure (the pool shell) made entirely of fiberglass material.

Other types of pools are built from multiple smaller components.

For comparison, a vinyl liner pool uses plastic or metal wall panels for side-wall support, a grout or vermiculite bottom for floor stability, and a vinyl liner laid over the walls and floors and vacuum-formed to create a seal. Concrete pools are typically formed from an outer cage of steel bars (rebar) on the walls and floor of the pool structure. This rebar is then encased in sprayed concrete, which will be covered in plaster once the concrete dries for durability and aesthetics.

We've put together a comprehensive pool type selector tool, which can help you decide whether you want a fiberglass, vinyl liner, or concrete installed in your backyard. Just click the banner below to take the quiz and get your results:

How are fiberglass pools made?

The short answer should be: very carefully.

Fiberglass pool shells are "built" in factory conditions, so pool buyers generally don't get to see their pool come together before the shell arrives at their home for installation.

However, we've filmed a number of videos in our facility to give you the first truly comprehensive behind-the-scenes look at the fiberglass pool shell manufacturing process. Much of it will be covered in the next sections of this article, but you can see a more detailed step-by-step breakdown at our dedicated manufacturing process page (click this link to see more).

No matter where you live or which pool shell you ultimately decide to install in your backyard, you should always interview manufacturers. Approach the interview with these goals:

- Understand their procedure;

- Find out if they employ experienced technicians in the factory;

- Vet skilled local builders to install the shell; and

- Obtain reference lists of customers you can talk to.

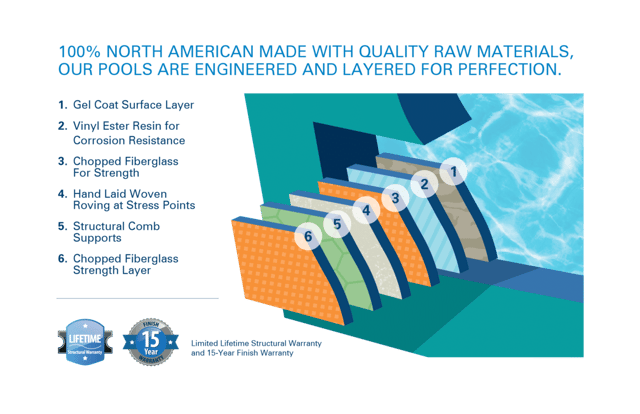

At River Pools, we manufacture pool shells through a proprietary process. This process is designed to bind together six layers of fiberglass and composite materials:

Our pool shells are typically just three-eighths of an inch thick. Compared to a concrete pool, which is 5-6 inches thick (including rebar), or a vinyl liner pool's 4-inch-thick wall panels, fiberglass pool shells are much thinner -- but they're extraordinarily durable.

The fiberglass pool shell mold

Fiberglass pools are constructed on molds, which does limit the range of shapes and sizes available for your pool project to whatever molds your manufacturer uses.

All River Pools molds are made from fiberglass reinforced with steel bars. Our molds are bright red-orange so it's easier to see when we've completed each layer -- we apply each layer of the pool shell on top of the mold, which means our pool shells are built from the inside (the surface gelcoat) out. Check out this critical first step in our manufacturing process below:

If you're still vetting fiberglass pool manufacturers, make sure to ask your manufacturer these three questions about the mold used to create your pool shell:

- Is the mold true and level? (will your shell be flush with the ground if properly installed?)

- Is the mold reinforced with steel? (is it durable?)

- Is the mold's finish smooth and regularly maintained? (is it free of defects?)

The surface gelcoat

The inside finish of a pool shell is what you can see and touch once your pool is properly installed and ready for swimming. It's called a gelcoat, and you can watch a quick overview of the the gelcoat application process below:

Our gelcoats are super smooth and durable, and all fiberglass pool gelcoats are inherently algae-resistant, which is a big upside to fiberglass pools that tends to make them much lower-maintenance than other types of pools over the long term.

The resin

Every time we apply chopped fiberglass to a pool shell, we first mix it with either vinyl ester resin or polyester resin. Resins add adhesive qualities to fiberglass, which makes it bond or stick to itself, and to any connected layers in the pool shell.

By the way, "resin" is pronounced reh-zin -- rah-zin is rosin, which you might use with a violin.

Here's an easy way to picture the process: papier-mâché.

Most of us have probably tried to make papier-mâché shapes by using strips of newspaper mixed with glue. My family often uses balloons as the "mold" for our papier-mâché creations.

If we painted the balloon with just a thin layer of glue, it wouldn't be papier-mâché, and the glue wouldn’t retain the balloon's shape after the balloon pops -- glue doesn't have a lot of inherent structural support. On the other hand, dry strips of newspaper won't even stay on the balloon, because they have no adhesive properties.

But if you mix newspaper with glue, and you've got structure and adhesion. It's pretty much the same as our mixture of fiberglass and resin. Fiberglass provides structure, while resin helps the structure stick together. In this example, resin is the glue to the fiberglass’ paper. When mixed and applied together, they keep the correct shape with proper support.

Check out the third video in our series, which covers our use of resin in more detail:

We use vinyl ester resin first because it’s waterproof.

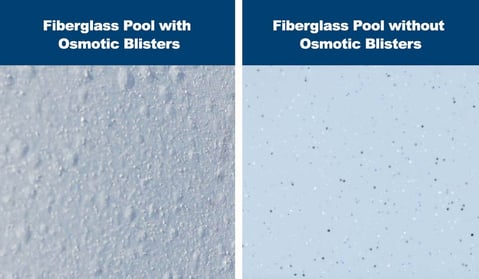

This layer of vinyl ester resin keeps water out of the polyester resin layers. If we didn't build our pool shells this way, interior layers of fiberglass might absorb water and produce visible bubbles in the gelcoat, called osmotic blisters by pool builders and manufacturers. Vinyl ester resin won't break down when exposed to pool water... but polyester resin can.

Using vinyl ester as a protective layer keeps your pool looking pristine, like the image on the right. If we didn't use vinyl ester, (some fiberglass pool manufacturers still don't!) you might wind up with a pool shell that looks more like the close-up image on the left:

Fiberglass pool gelcoat with and without osmotic blistering

Fiberglass pool gelcoat with and without osmotic blistering

By using 100% vinyl ester resin in the first layer of chopped fiberglass, we effectively seal off the gelcoat from the interior layers, so no water can affect the polyester resin layers further in. This prevents bubbles or blisters from forming in the gelcoat, which might eventually ruin the smooth finish of your fiberglass pool.

When interviewing manufacturers, ask if their warranties will cover the gelcoat if osmotic blisters form. A quality fiberglass pool manufacturer should be confident enough in their process to make this promise.

This video goes into more detail on our use of chopped fiberglass and resin:

Most pool buyers start out knowing next to nothing about the types of pools they can get for their backyards. If you've read this far, you're already way ahead of the pack.

We encourage you to keep reading more about fiberglass pools, because an informed buying decision is always the best decision... but we're always available to talk you through your options, timelines, price ranges, and any other important element of your prospective pool project. Just click the button below to set up a call with one of our fiberglass pool experts:

The quality check

Once we've applied all the necessary layers to create a durable pool shell, we pop it off the mold and look over every square inch of the shell for any cracks or inconsistencies in the fiberglass.

Different manufacturers may use different processes, and even different materials, but every reputable manufacturer should perform a thorough quality check on every pool shell.

Manufacturers should also weigh the pool shell to make sure it's been built to within 5% of its design specifications. A pool shell that's more than 5% lighter or 5% heavier than specified may not have enough material, or its material may be faulty.

Ask your pool builder and/or manufacturer for a dig sheet (the design specs). This can help you compare the listed weight to the weight written on the side of your pool shell. Of course, it's better to check this number out before your pool shell is shipped to your house. Ask for a photo.

Want to see a live walkthrough of our quality inspection process? Check out this video:

The two stages of the process

Putting a fiberglass pool in your backyard is a two-stage process.

We already covered much of the manufacturing stage. This is distinct from other pool types like concrete and vinyl liner pools, which are constructed as they're installed.

Where every individual piece and part of concrete and vinyl liner pools must be put together on site, the single largest component of a fiberglass pool project (the pool shell) is ready to be put in the ground and filled with water practically from the moment it arrives at your home.

The installation process for fiberglass pools is much shorter than for other pool types because most of the work has already been done before your pool builders show up.

Let's take a look at what happens after your builders show up with your pool shell...

How are fiberglass pools installed?

Most fiberglass pool shell manufacturers won't employ the people who'll install your pool. This makes interviewing prospective installers an essential part of your fiberglass pool buying process. This can help you verify their experience and procedures, and it gives you the chance to check your installer's customer references.

At River Pools, we manufacture world-class fiberglass swimming pools for installation across North America and have a wide variety of models to choose from. Try our inground pool quote tool today to see how much a fiberglass pool will cost you, or contact us directly for more information. This helps us maintain a consistent and seamless pool project experience for all customers.

This is our process for installing your pool (click this link for more detail):

- Excavate the soil.

- Set and level the pool.

- Install the pool’s plumbing and filter systems.

- Backfill the pool shell.

- Install the patio and coping.

- Install the pool fence and other optional décor.

The fiberglass pool installation process typically takes just a few weeks, which means you should be able to enjoy your pool all summer long instead of having a torn-up eyesore of a backyard for months and months.

Here's a video we recently put together with real-time video from one of our installation projects:

What does a fiberglass pool cost?

On average, most fiberglass pool projects will cost between $65,000 and $100,000 for a turnkey installation. Extra features and upgrades, such as pool waterfalls, pool lighting, and/or fencing, can push your price range higher.

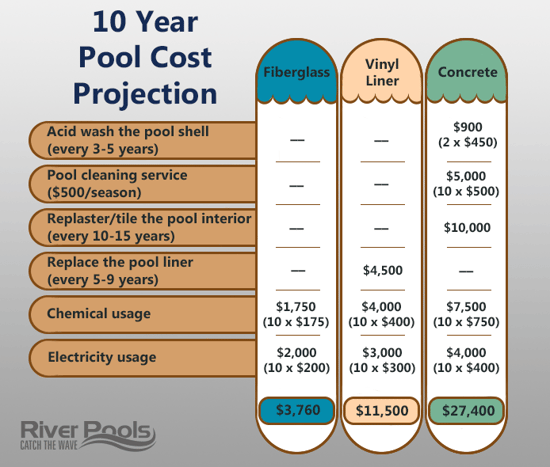

After installation, you'll typically spend about $375 a year on maintenance and upkeep over the life of your fiberglass pool -- in other words, it'll only cost you about $3,750 over 10 years. This is significantly less than you'll pay to maintain other types of inground pools -- a vinyl liner pool can require an average of $1,150 a year to maintain, and a concrete pool will set you back as much as $2,740 a year in maintenance costs.

Fiberglass' low-maintenance qualities are some of its biggest benefits to pool buyers and owners.

Want a customized price estimate for your pool project? Click the button below:

What are the pros and cons of fiberglass pools?

We specialize in and advocate for fiberglass pools because we truly believe they’re the best long-term fit for most pool buyers... but fiberglass pools aren't flawless, and they do have some downsides. Here are some pros and cons for fiberglass pools:

Advantages (pros)

- Fast installation

- Durable

- Low maintenance

- Lower lifetime costs

- Attractive design options

- Compatible with salt water systems

Fast installation

Installation for most fiberglass pool projects usually take between three and six weeks, from the first day your builders show up to the first day you can take a dip in your new pool.

By comparison, many concrete pool installations take between three and six months to complete.

Durable

Fiberglass is strong. You won’t have to worry about puncturing the gelcoat or cracking the structure while playing in your pool every day. Your dogs (or cats, or any other water-loving pets) can play in the pool without damaging the surface with their claws.

The gelcoat of a high-quality fiberglass pool shell never needs to be refinished, as long as it's been made, installed, and maintained properly.

Low maintenance

A fiberglass pool's gelcoat is smooth and algae-resistant. This helps pool owners avoid costly and time-consuming surface scouring, and it allows you to use fewer algae-killing chemicals, which is much better for your skin, eyes, and hair. Fiberglass won't affect the pool water chemistry, so you won’t need to add acids to balance the pH.

All the problems mentioned here are common to concrete pools.

Lower lifetime costs

Fiberglass pools require less electricity and fewer chemicals for maintenance—this not only saves you that time and effort, but it also cuts down your costs.

Over a 10-year period, you’ll generally spend less than $4,000 to maintain a fiberglass pool. If you owned a vinyl liner pool, you'd need to spend nearly $12,000 for 10 years of maintenance. A concrete pool often costs over $27,000 to maintain over 10 years! Remember the annual maintenance costs we mentioned earlier? Here's a more detailed breakdown of each component of those costs:

Attractive design options

The first fiberglass pools looked simplistic, and were, quite frankly not particularly attractive.

Nowadays, you can customize your fiberglass pool to fit any aesthetic, with colored finishes, spas and/or tanning ledges, ceramic waterline tile, water features, LED lights, and many other options. Many fiberglass pool shells now include built-in tanning ledges, benches, and spas.

Fencing can be as fancy as you'd like, as long as it meets safety regulations.

Compatible with salt water systems

The salt from salt-water chlorinators will wear down concrete and metal, such as the metal wall panels and coping used for vinyl liner pools. Fiberglass won't react to salt water, and salt water systems are generally cheaper (and easier on the body) than chlorine-based systems. Using a salt water system with your fiberglass pool can provide high-quality water with low maintenance.

Disadvantages (cons)

Limited options

Fiberglass pools generally won't be more than 16 feet wide, 40 feet long, and 8.5 feet deep. These dimensions are controlled by highway transport laws and regulations, because any fiberglass pool shell you choose will need to be trucked from a factory or dealership to your home.

Manufacturing fiberglass pool shells on pre-designed molds is great for quality control, but it will limit you to the shapes and sizes of any molds used by your manufacturer.

There might be limited customization in terms of the basic designs of fiberglass pool shells, but plenty of features can be added.

The growing popularity of fiberglass pools has also created a bit of a positive feedback loop between pool manufacturers and pool buyers. Higher demand gives manufacturers reasons to create more designs (more molds), which gives pool buyers more options... which creates more demand. We make fiberglass pools in quite a few different shapes and sizes, and many pool buyers find a design that works brilliantly in their backyards.

Higher initial (installation) costs than a vinyl liner pool

On average, most fiberglass pool projects cost between $65,000 and $100,000. This includes both manufacturing and installation. Extensive retaining walls, water features, or other special add-ons will increase the project price further.

Concrete pools can cost more, but a vinyl liner pool may only cost between $35,000 and $65,000 to install. However, fiberglass pools have the lowest long-term cost of ownership, as we mentioned earlier, which can make them the best long-term investment for anyone who plans to stay in their home for years to come.

How can I find a good fiberglass pool manufacturer?

We recommend you interview multiple manufacturers to compare their methods and contact any provided customer references.

If you have trouble finding manufacturers in your area, ask a reputable fiberglass pool builder or installer about the manufacturers they recommend. You should vet your builders just as you vet any manufacturers -- we'll cover that in the next section.

We're not here to toot our own horns, (well... maybe just a little) but many of our manufacturing processes and procedures have been adopted as industry standards. That standard is known as the River Pools Way, and it looks for several critical qualities in every finished pool shell:

- A level, reinforced, smoothly finished mold

- Climate-controlled factory conditions for optimal gelcoat curing

- 100% vinyl ester resin in the first fiberglass layer (beneath the gelcoat)

- Reinforced stress points using woven roving

- Strengthened sides using "honeycomb" material

How can I find a good fiberglass pool installer?

We also recommend you interview multiple installers so you can compare their answers. Speak with their customer references as well.

Ask installers how they have or would deal with these common installation problems:

- Settling or shifting of the pool shell

- Leaks in plumbing lines and pool fittings

- Separation between pool and patio

- Bulges in side walls

Look for these solutions, which we use in our advanced installation methodology:

- Fusing the pool shell and patio together

- Plumbing straps to secure plumbing to pool shell

- Using schedule 40 PVC hard pipe

- Using crushed/chipped stone for backfill

- Encasing plumbing in stone to prevent settling

- A 12-inch-thick concrete bond beam around the pool perimeter

- A sump pipe to monitor and remove ground water

What does all of this mean for me?

Fiberglass pools have advanced and evolved since their earliest iterations in the 1950s. Today's fiberglass pools are cutting-edge high-end products installed in backyards around the world.

Some fiberglass pools installed in the 1960s are in use today... but they're not anywhere near as stylish as a fiberglass pool you might have installed in your yard this year.

We expect our fiberglass pools to last for decades. In fact, River Pools provides a lifetime structural warranty for all the fiberglass pools we manufacture.

If you want keep researching fiberglass pools for your family, please reach out and contact us to request pricing and dial in the specific details of your project. We also have a comprehensive learning center to support your self-directed research. You can also post any questions you may have below in the comments on this article.

We've collected all the best and most up-to-date information on fiberglass pools in one detailed ebook, which you can download by clicking the banner below:

Further reading:

The Basics of Manufacturing and Installing a Fiberglass Pool

Fiberglass FAQ: 14 Most Common Questions about Fiberglass Pools

How Much Is My Fiberglass Pool Really Going to Cost?

Editor's Note: This article was originally written by Jason Hughes on October 9, 2017. Any opinions expressed are those of the author. Any prices referenced were based on information that was readily available at the time.

River Pools is a brand of inground fiberglass pools produced in a manufacturing facility in Fortville, IN. While our expertise is in manufacturing fiberglass pools, we have access to a network of installers with expertise relating to project design, installation, and pool service. We often tap into this knowledge base and share information freely with homeowners, just like you, considering installing a swimming pool in your backyard.