5 Keys to Perfect Fiberglass Pool Plumbing

“No runs, no drips, no errors.”

That’s what Harold Johnson, the man who introduced me to the pool business over 17 years ago, used to say after every successful plumbing installation around a pool.

The fact is that most runs and drips are caused by plumbing errors, and this article is dedicated to defining several best practices when installing plumbing around an inground fiberglass pool.

What's the key to perfect fiberglass pool plumbing?

- Use proper backfill

- Use only rigid PVC

- Secure the plumbing

- Pressure-test the plumbing

- Heat-bend the rigid PVC

1. Use proper backfill

Believe it or not, the healthiest thing you can do for plumbing around a fiberglass pool has nothing to do with plumbing at all. It has to do with the installation and type of backfill material.

The fact is that most leaks around fiberglass pools result from pressure exerted on the plumbing from settling backfill material.

Although there are many contractors who successfully use sand as a backfill material, we prefer gravel because it compacts upon placement and does not require “washing” with water to achieve compaction.

When not meticulously placed, sand backfill will often settle as much as 12”–18” around the outside of a fiberglass pool.

Consider the downward pressure placed on the plumbing and thru-wall fittings of the pool. The use of gravel backfill alone would have eliminated about 75% of all of the plumbing problems we’ve seen around fiberglass pools.

2. Rigid PVC over flexible PVC pipe

I wrote a somewhat controversial article on Rigid vs. Flex PVC that has spawned some interesting comments. Here are a few excerpts from completely random and unsolicited pool owners:

“I developed a suction problem last summer in my in ground pool. My installer told me he felt it was a termite problem. I started digging and sure enough, my skimmer line flex pipe was riddled with bug chews…My installer came out and replaced the two lines with new flex pipe. I flooded the trench with 5 year termite killer and back filled. After 1-2 months, I again developed a suction problem. I closed the pool for the winter and just this week dug up my underground lines. Sure enough, my skimmer line was again destroyed by bugs.”

“Last year I noticed that I could not bleed the air out of my inground pool pump. I checked to see if any of the connections has leaks. None of them did. We started to dig, and found 5 out of 6 pipes leading from the filter to the concrete had multiple tiny holes. All 6 pipes were replaced. Now just a few days ago I am having the exact problem as last year. We even had a Termite inspection of the house and yard, and were told there was no visual sign of termites. How is it that the pool company is not responsible for using materials that are not suitable for inground pools?”

“We found several "bug chews". No termites have been found but, several ant colonies have been found in the area of the flex….Pool installers in Michigan only warranty their work for the first year. So unless the bugs destroy the flex immediately, the homeowner is the loser….My pool guy has had several problems using flex and has given up on it. Whether it's the flex, or the sand back fill causing the bug problems makes little difference to me…..I also would like to note: my pool guy is still in business and is now quite busy with chew repairs.”

We’ll let the experiences of these unlucky folks speak for themselves. It’s best to avoid flexible PVC if at all possible.

3. Secure the plumbing

We feel it’s best, even with gravel backfill, to “tie” the plumbing up with straps or wire to prevent settlement.

This is done by drilling holes through the fiberglass coping of the pool and running the strap or wire through the holes and around the plumbing.

We do this approximately every four to five feet, and wherever there’s a thru-wall fitting. This also allows us to pre-plumb the pools before setting them into the hole.

4. Pressure-test the plumbing

This is an obvious one, but it needs to be stated.

All plumbing lines need to be pressure-tested to ensure there are no leaks.

5. Heat-bend the rigid PVC pipe

One of the arguments against rigid pipe is that it needs fittings in order to make a turn. Flex pipe has the ability to bend around turns and thus eliminates the need for fittings.

There’s no doubt that reducing the amount of glued fittings is preferable. Heat-bending rigid PVC pipe gives the best of both worlds.

As shown in our heat bending video, heat-bending transforms rigid pipe into a temporarily flexible material that gives the fluidity of flex pipe with the added strength and durability of rigid PVC.

How do you know if your pool builder uses good plumbing practices?

There you have it: 5 best practices for installing plumbing around an inground fiberglass pool.

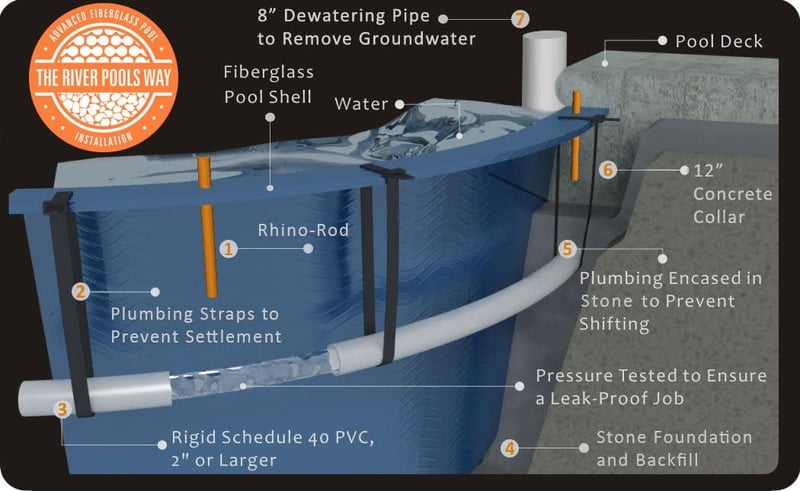

When you're choosing your pool builder, ask if they install using The River Pools Way:

- Clean, crushed stone for backfill

- All Schedule 40 rigid PVC pipe

- Plumbing straps secure plumbing to pool shell

- "River Rod" fuses patio and pool shell together

- Plumbing encased in stone to prevent shifting

- 12"-thick concrete collar around perimeter of pool

- Sump pipe for monitoring/removing groundwater

Our commitment to excellence led us to pioneer best-practice methods that surpass the industry standard.

When properly implemented, The River Pools Way: Advanced Installation eliminates the most common problems in fiberglass pool installations.

Comments and questions always welcome.

Thanks for visiting!

Up Next:

The River Pools Way: Fiberglass Pool Installation Problems Solved

Large Fiberglass Pools FAQ: Cost, Designs, Pros and Cons

The Pros and Cons of Fiberglass Pools

Editor's note: This blog article was originally published in August 2010 and has been updated and revamped for accuracy and appearance.

Editor’s note (5/3/24):

This article was written by Jason Hughes, (Founder, River Pools Virginia, Genesis Course Instructor). The opinions expressed are those of the author. Any pricing information is based on information that was readily available at the time of publication.

River Pools is a brand of inground fiberglass pools produced via the River Pools division of the manufacturing facility in Fortville, IN. While our expertise is in fiberglass pool manufacturing, we are part of an extensive network of experts relating to all things inground pools. Our own collective experience from over the years spans manufacturing, project design, installation, and pool service. We often tap into this knowledge base and share information freely with homeowners, just like you, who are considering having a swimming pool installed in your backyard.