When I first visited River Pools in person, the first things I noticed were the...red-orange lumps outside.

When I first visited River Pools in person, the first things I noticed were the...red-orange lumps outside.

What kinda yard decorations are those?

The answer: Not decorations at all. (Whew!)

Turns out, these are pool molds—we make them ourselves and then use them to manufacture our fiberglass pools. Fancy, right?

But what does all that really mean?

Let's talk about these weird-looking lumps:

- What a pool mold is, and what it is not

- How we make a mold for a fiberglass pool

- How we use a mold for a fiberglass pool

- How we maintain a mold for a fiberglass pool

What a fiberglass pool mold is, and what it is not

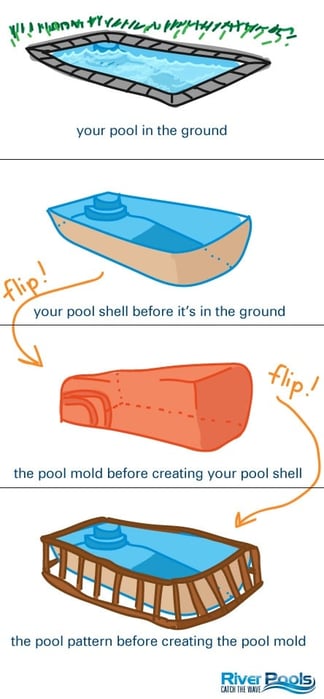

There are 3 steps to creating a new fiberglass pool:

- The pattern (or plug)

- The mold

- The shell

For right now, let's go with a pretty high-level summary—enough to give you an overview, but not overwhelm you with details. We'll do that later.

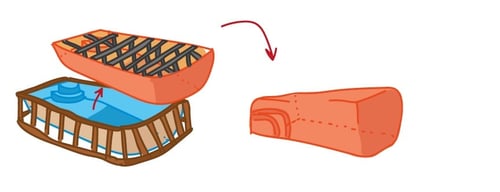

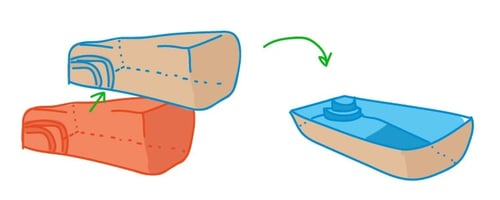

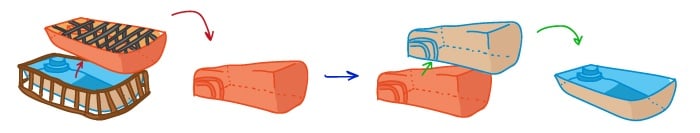

In the most basic sense, the production process is 3 versions of the same shape, just flipped one way or the other.

This can be a little hard to envision, especially if you're spacially challenged like me. It took me a while to be able to visualize it. Maybe this illustration will help. (Remember, you're flipping the shape between each stage.)

The pool pattern

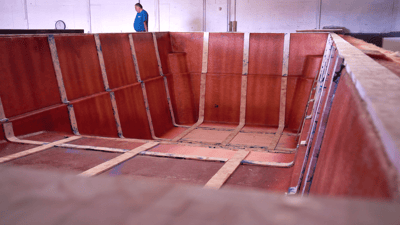

First, the manufacturing team builds a huge wood frame that creates the pool shape. This process is super cool to watch, by the way.

From the outside you see supports, but the inside looks roughly the way your pool will.

Note: The pattern itself is right side up.

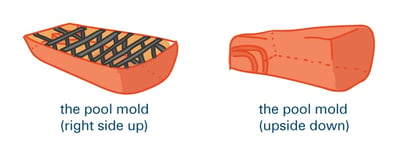

The pool mold

We build the mold right-side-up, inside the pattern.

This starts with the outer gelcoat, then fiberglass, and then a network of steel beams welded together.

Intense, right?

They support the mold and ensure it keeps the same shape despite changes in weather that could cause the material to expand and contract.

After we remove the mold from the pattern, we flip the whole mold upside down.

After we remove the mold from the pattern, we flip the whole mold upside down.

Yeah, it lives to create the shape of the inside of a pool flipped upside down. (Feel free to squint.)

That's why, when sitting around, the pool mold honestly doesn't look like a pool at all.

The pool shell

The pool shell

The pool shell is your actual pool.

We build it on top of the upside-down mold.

Then we flip it right-side-up and install it in your backyard for you and your family to enjoy. Woo!

How we make a pool mold

Let's say we've come up with a cool new fiberglass pool design. I'll call it The Narwhal.

Over the course of 3–6 months, our fiberglass pool manufacturing team builds the pattern—the wooden framework for the Narwhal pool design. It looks like the pool itself, but with all those wooden support beams on the outside.

When the pattern is complete, we start building the Narwhal's mold inside it.

First, we spray red-orange gelcoat all over the inside of the pattern—that's the mold's outer layer.

We spray multiple layers of fiberglass over that, which creates the mold structure and gives it a solid shape that will hold up when we separate it from the pattern.

(Otherwise it would be like forgetting the paper when papier-mâchéing a balloon. The glue, or in this case the gelcoat, doesn't hold the shape by itself.)

Once that solid frame is set up, we weld steel bars up, down, and across it to prevent any shape changes from expansion and contraction.

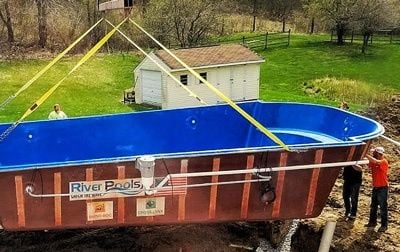

When the Narwhal mold is ready—gelcoat plus fiberglass structure plus steel bars—we use a crane to lift it out of the wooden pattern.

We pull it up and out, and then set it upside down on wheels so we can move it around as needed (i.e., without having to pull out a crane every time).

How we use a pool mold

We've made the mold... Now let's use it!

Once we flip the mold upside down, it shapes the inside of the Narwhal pool.

We layer the pool shell on top of it, first the colorful gelcoat (the lovely outer layer you see when it's in the ground) and then the thick fiberglass structure (usually brown). When a Narwhal pool shell is complete, we lift it off the mold, trim the edges, and flip it right-side-up.

.png?width=241&name=pool%20shell%20separated%20from%20mold%20(smaller%20with%20labels).png)

One Narwhal fiberglass pool, ready to install in your backyard!

Want to learn more about the manufacturing process for our fiberglass pools? We'll show you exactly how we build the pool shell, step by step—and why we developed these groundbreaking best practices!

We can use the same mold many times, which is awesome, given how long it takes to make each new one.

How we maintain a pool mold

A pool mold can last forever and a day as long as it's well maintained. (Hey, that's true of your fiberglass pool too!)

The steel frame inside the mold means that it won't collapse from stress or change shape. The potential maintenance issue is the gelcoat (the orange outside layer).

If we see orange flecks on a pool shell's blue gelcoat, we know that the mold's gelcoat needs some TLC.

Fun fact: that's why we make the mold's gelcoat red-orange! It's a bright color and so different from the pool's color that it's obvious if one gelcoat sticks to the other.

How River Pools is unique as a fiberglass pool manufacturer

Produced in a manufacturing facility in Fortville, IN, we at River Pools specialize in fiberglass pools.

As firm advocates of fiberglass pools, we're upfront and honest about both the pros and cons. They can be installed quickly, are very durable, are extremely easy to maintain, and look beautiful. However, their initial cost can be higher than vinyl liner pools, and the shapes and sizes are not as customizable as concrete or vinyl liner pools. They may not be for everyone, but we've never had a dissatisfied customer.

On top of that, we're 100% transparent about how we build our pools because we're confident in the quality of the techniques and the final product.

We developed our unique, ground-breaking manufacturing and installation methodologies to prevent the problems common to the pool industry, such as:

- Osmotic blisters in the gelcoat

- Too much flexibility or rigidity in the pool shell

- Cracks in the shell's stress points

- Bulges in the side walls of the pool

- Settlement or shifting of the pool shell

- Leaks in plumbing lines and around jets and other pool fittings

- Separation between the pool and patio

That's a lot of potential problems, right? No worries. We've accounted for all of them.

With our techniques, you get the strongest, most durable pool possible that needs the least maintenance possible.

And our manufacturing warranty (which you can read anytime) backs that up. Remember, if your pool manufacturer has a poor or hidden warranty, it’s a bad sign about their confidence in the product.

(As a reminder, the manufacturing warranty for any fiberglass pool should cover the structure and the surface, and it's separate from the installation warranty.)

Our Lifetime Structural Warranty

- Covers structural failure due to defects in workmanship or materials

- Covers the cost to drain and brace the pool

- Covers the cost to refill the pool and replace chemicals

- Is transferrable

Our 15-Year Surface Warranty

- Covers osmotic blisters for a period of 15 years

- Is transferrable

Up Next:

The Basics of Manufacturing and Installing a Fiberglass Pool

What Can You Expect From a Fiberglass Pool Kit?

The Pros and Cons of Fiberglass Pools

Editor's Note: This article was originally written by Holly Jender on June 5, 2018. Any opinions expressed are those of the author. Any prices referenced were based on information that was readily available at the time.

River Pools is a brand of inground fiberglass pools produced in a manufacturing facility in Fortville, IN. While our expertise is in manufacturing fiberglass pools, we have access to a network of installers with expertise relating to project design, installation, and pool service. We often tap into this knowledge base and share information freely with homeowners, just like you, considering installing a swimming pool in your backyard.

Topics: